News

Lightweight Foamed Micro-crystallized Panel (Ⅷ)

2025-08-18

1、Lightweight microcrystalline stone wall materials

Lightweight microcrystalline stone is a material that integrates multiple functions such as decorative integration, thermal insulation, fire resistance, lightweight high strength, waterproofing, mildew prevention, corrosion resistance, weather resistance, and sound insulation. This component is ultimately applied to building exterior walls, interior walls, interior decoration, soundproofing and noise reduction walls, fireproof walls of buildings, and industrial anti-corrosion walls.

|

Product Category |

Main Features |

Product specifications (mm) |

|

Lightweight microcrystalline substrate |

100 foam matrix, density 0.2-0.4 g/cm³ |

1600x1200x100 |

|

Microcrystalline sandstone-faced lightweight microcrystalline stone wall material |

Integrated firing of microcrystalline sandstone surface and foaming |

1600x1200x100 |

|

Gravel-faced lightweight microcrystalline stone wall material |

Integrated sintering of natural gravel and foamed matrix |

1600x1200x100 |

|

Double-density lightweight microcrystalline stone |

Integrated firing of heavy foam layer with lightweight foam matrix |

1600x1200x100 |

|

Lightweight microcrystalline anti-corrosion brick |

3mm anti-corrosion layer co-fired with foam substrate in one piece |

1600x1200x100 |

|

High-density lightweight microcrystalline substrate |

Density 0.45~0.6g/cm pure foamed substrate |

1600x1200x100x(15-100) |

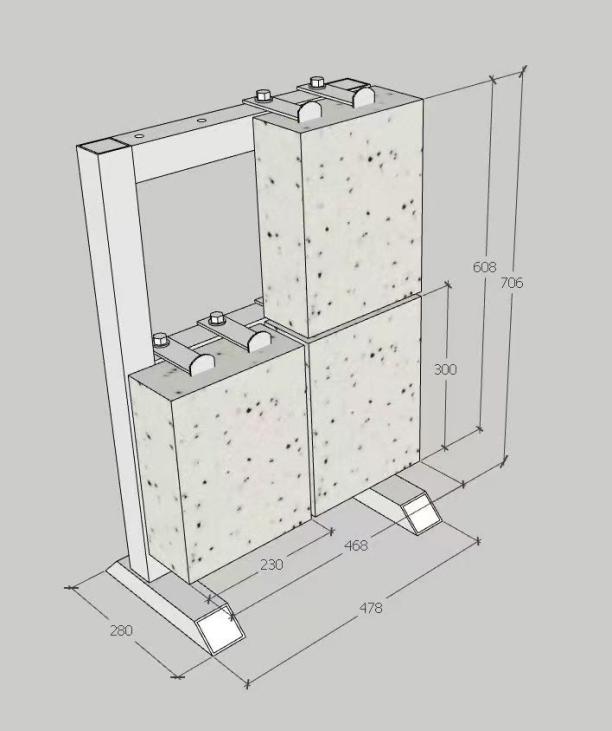

2、Lightweight microcrystalline stone unit curtain wall

By using construction methods such as light steel keel, embedded rebar, metal edge sealing, hanging nodes, and modular seams, new materials are made into safe and reasonable high-precision standardized components. This provides architects with standard bases and methods for further creation, turning lightweight microcrystalline stone into a puzzle board in their hands, allowing them to freely create myriad architectural wonders in prefabricated buildings.