News

Lightweight Foamed Micro-crystallized Panel (Ⅵ)

2025-08-07

- Lightweight and High Strength

It is lightweight and can float on water all year round, with relatively high strength. Its strength-to-weight ratio is 4 times that of cement, and 8–11 times that of foamed ceramics and foamed cement.

- Thermal Insulation and Sound Insulation

The minimum thermal conductivity can reach 0.057 W/m·k. For materials with a specific gravity of 0.3, the sound insulation capacity can exceed 50 decibels.

- Fire Resistance and Flame Retardancy

It has a fire resistance rating of Class A1, and its ablation resistance exceeds the national standard by more than 50 times. Its fire-resistant temperature is the highest among inorganic foamed products, approximately 1.5–2 times that of foamed ceramics and foamed cement.

Fire Resistance Performance of Lightweight Microcrystalline Stone Wall Material

|

Number |

Inspection Item |

Inspection Method |

Standard Requirement |

Inspection Result |

||

|

1 |

Temperature Rise in Furnace (°C) |

GB/T5464-2010 |

A1 |

≤30 |

2 |

3 |

|

2 |

Sustained Burning Time (s) |

GB/T5464-2010 |

0 |

0 |

0 |

|

|

3 |

Mass Loss Rate (%) |

GB/T5464-2010 |

≤50.0 |

22.3 |

0.7 |

|

|

4 |

Calorific Value (MJ/kg) |

GB/T14402-2007 |

≤2.0 |

0.2 |

0.1 |

|

- Hydrophobicity, Corrosion Resistance, and Weathering Resistance

The material exhibits hydrophobic properties at the molecular structure level, with a closed-cell rate of over 75% in the foam, and it possesses corrosion resistance comparable to acid-resistant bricks.

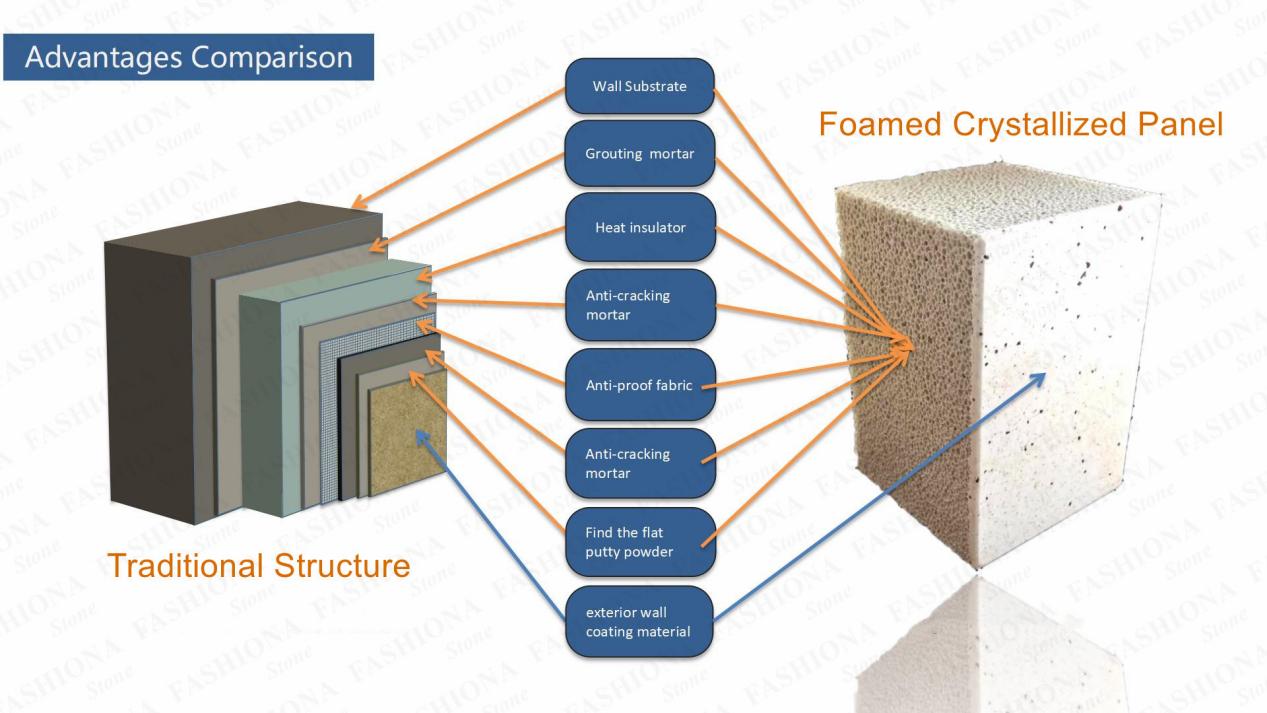

- Integrated Decoration and Healthy Environmental Protection

Thanks to its unique integrated sintering technology for the decorative surface composite layer and excellent functional gradient characteristics, the product fulfills most functions of traditional wall materials except for load-bearing. The raw material itself is a silicon-based material, which, after high-temperature crystallization, contains no radioactive elements. Both waste from production and application can be recycled and reused.