News

Lightweight Foamed Micro-crystallized Panel (Ⅴ)

2025-08-04

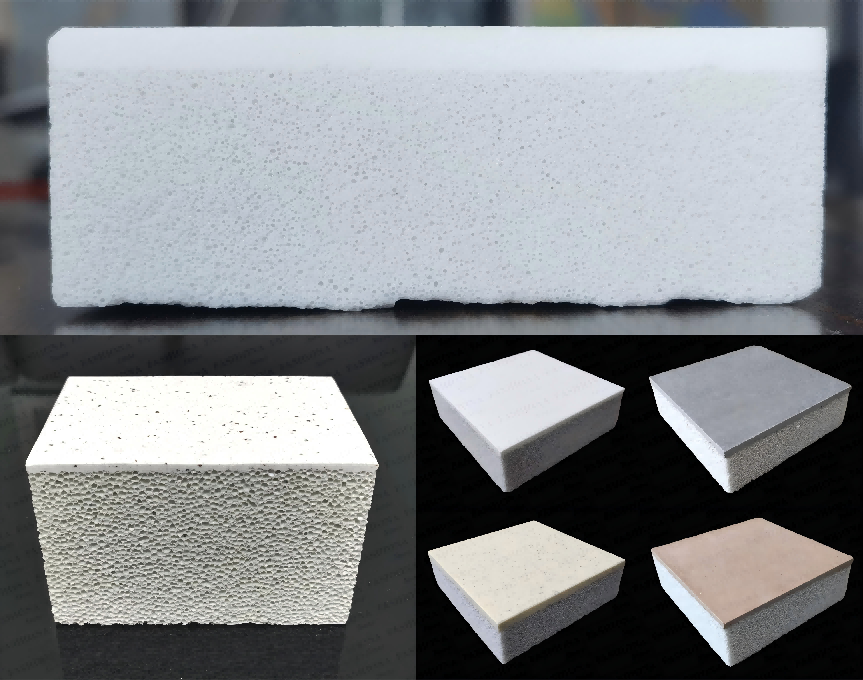

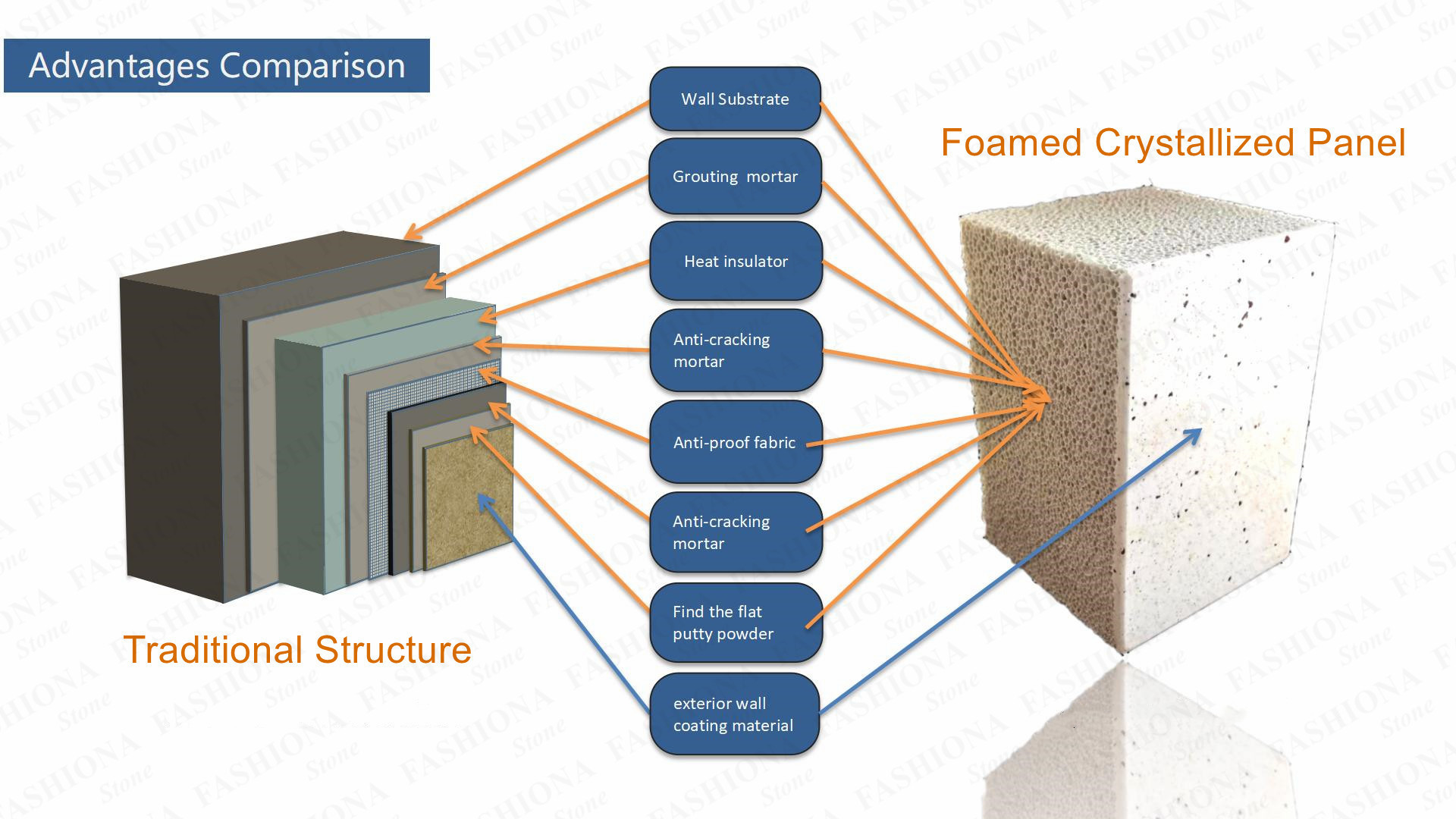

The surface layer of lightweight microcrystalline stone and microcrystalline foam are sintered together at high temperatures.

The finish is a traditional microcrystalline glass structure, which is non-absorbent, weather-resistant, and UV-resistant.

The microcrystalline foam has a honeycomb pore structure that provides fire resistance, sound insulation, and thermal insulation, while remaining lightweight and possessing a uniform internal structure.

The two melt and interpenetrate at 1200°C, forming an indivisible, solid whole. This makes it a superior alternative to traditional aluminum honeycomb composite panels.

Performance Indicators of Lightweight Micro-crystallized Stone

|

Item |

Requirements |

|||||||

|

Md2 |

Md3 |

Md4 |

Md5 |

Md6 |

Md8 |

Md10 |

||

|

Density / kg/m³ |

≤200 |

≤300 |

≤400 |

≤500 |

≤600 |

≤700 |

≤800 |

|

|

Strength Grade |

MU1.5 |

MU3.0 |

MU4.5 |

MU6.0 |

MU8.0 |

MU10 |

MU15 |

|

|

Thermal Conductivity Coefficient / W/(m·K) |

≤0.078 |

≤0.11 |

≤0.15 |

≤0.18 |

≤0.25 |

≤0.30 |

≤0.40 |

|

|

Water Absorption Rate / % |

≤5.0 |

≤4.0 |

≤3.0 |

≤2.0 |

||||

|

Combustion Performance Grade |

A1 Grade |

|||||||

|

Radioactivity |

Comply with the provisions for main building materials in GB 6566 |

|||||||

|

Sound Insulation / dB |

≥32 |

≥35 |

≥38 |

≥40 |

≥41 |

≥42 |

≥44 |

|

|

Bending Failure Load / KN/m² |

≥0.5 |

≥1.0 |

≥1.5 |

≥2.0 |

≥2.5 |

≥3.0 |

||

|

Impact Resistance / times |

≥5 |

|||||||

|

Hanging Force / N |

≥1000 |

|||||||

|

Freeze Resistance |

Hot - summer and Warm - winter Region |

F15 |

Mass Loss Rate ≤ 5% |

|||||

|

Hot - summer and Cold - winter Region |

F25 |

|||||||

|

Cold Region |

F35 |

|||||||

|

Severely Cold Region |

F50 |

|||||||

As a newly developed exterior wall covering material,.including wall applications, lightweight microcrystalline stone is undoubtedly the highest-quality product currently available and is poised to become a shining star among wall materials