News

Foamed Crystallized Panel

2023-10-16

As a high-end building decoration material, stone is widely used in indoor and outdoor design, curtain wall decoration, public facilities and other fields. Common stones on the market are mainly divided into natural stone and artificial stone.

Natural stone refers to the general term for materials that are mined from natural rock masses and processed into blocks or plates. The natural stones used for architectural decoration mainly include granite and marble.

Artificial stone is a synthetic material, which can be divided into terrazzo and synthetic stone according to the process. Terrazzo is forged from cement, concrete and other raw materials; synthetic stone is made from natural stone gravel, plus adhesives, etc., which are pressurized and polished.

With the continuous updating of production technology and equipment, the product quality, appearance and cost performance of Chinese artificial stone have caught up with or exceeded the international advanced level.

China is a major producer of artificial stone and has the most diverse and complete production equipment and production capacity. Among them, sintered glass-ceramic marble has the largest production capacity and color variety in the world, especially rolled nano-glass-ceramic marble, which is currently only produced in China.

On an academic level, they are called crystallized glass stones. With silicon oxide as the main component, it is melted and crystallized into a slab at different temperatures of 1200 to 1600°C. Containing no resin or any colored binders, it is a purely inorganic material that provides long-lasting weather resistance and UV protection. It is widely used in the field of building decoration materials, such as wall and floor paving materials, kitchen and bathroom countertops, special-shaped curves or cylindrical surfaces, building exterior curtain walls, etc.

Micro Crystallized Glass Stone

Full body slabs

Micro Crystallized Glass Stone was first discovered by the American Corning Glass Company in the 1950s. Later, industrial production was realized in Japan. Starting in the 1990s, mass production began in China and was gradually introduced to the international market.

Because this material is a glass-like plate, their names all contain "glass", for example, microcrystalline glass/marble glass/microcrystalline marble/microcrystalline marble/ceramic glass ceramic plate/ceramic glass stone/solid microcrystalline Crystallized glass/Crystalline glass/Glass/Glass Thassos etc.

Crystallized Glass Stone is harder than natural stone, has excellent weather resistance, can resist acid rain and ultraviolet damage, and will never change color or fade. It is very suitable for the exterior walls of buildings, so it is also the best substitute for natural Greek Crystal White.

Glass tassos is an industrially manufactured product that is free of color penetration, has low porosity, requires no special maintenance, can be cleaned by conventional means, and is more readily available and less expensive than natural crystal white. Because of its excellent non-absorbent properties, it is also often used in indoor humid spaces such as kitchens and bathrooms.

The maximum size of the product plate is 320×160cm, and the thickness can be customized from 12-150mm; the surface treatment of ordinary products is polished, and sandblasting or leather surface treatment can also be customized.

The leather veneer is the naturally generated surface before polishing, that is, the Pre-polish veneer, which is close to the glossiness of natural crystal white. When applied to floors coverings, it can enhance the anti-slip function.

China is rich in mineral resources and has mature manufacturing technology and equipment accumulated over many years. There is plenty of room to develop more colors.

Crystal Porcelain Tile

Two layer tiles

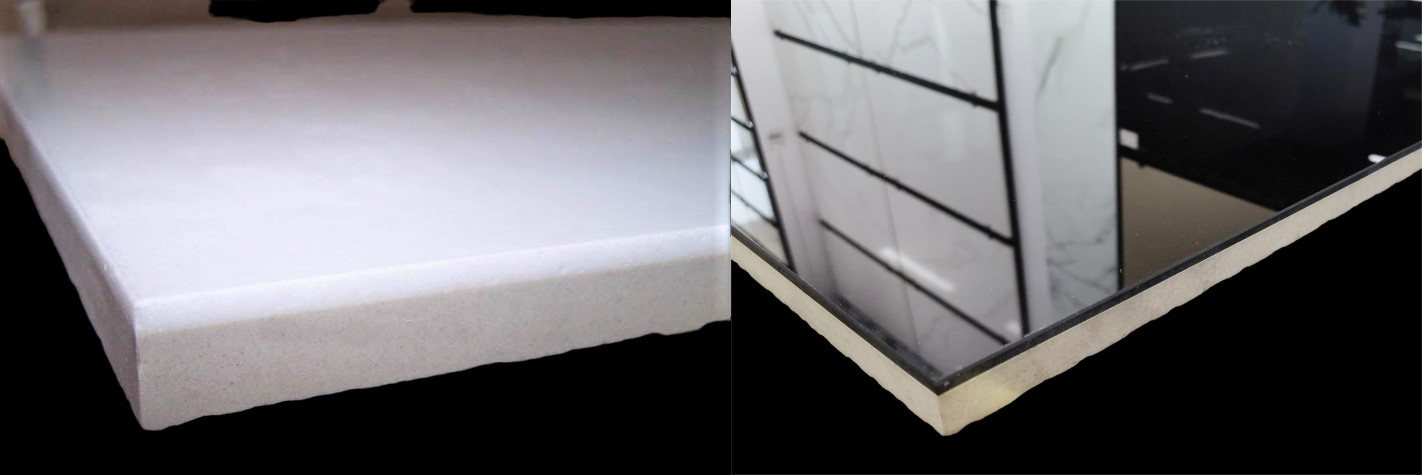

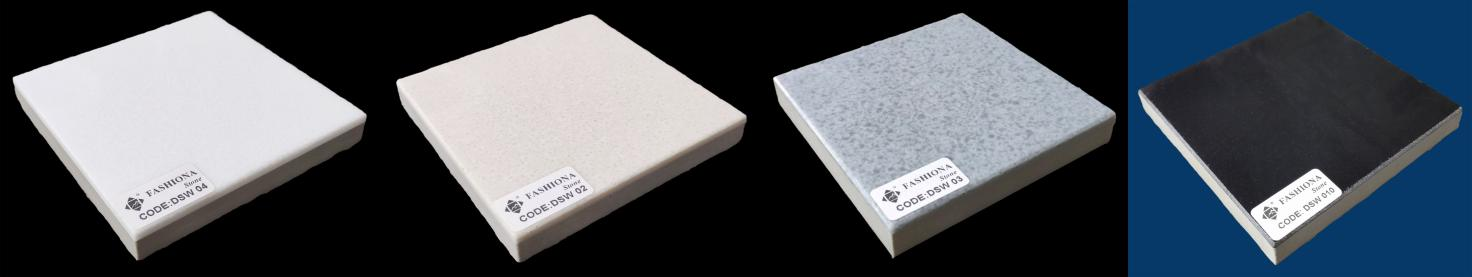

Composite crystallized tiles are a perfect combination of crystallized glass and porcelain. They were successfully developed in Foshan, China in 2003 by Fashionastone and BODE Ceramics.

This is a two-layer composite material. The design of the product is inspired by Fashiona's full-body crystallized glass stone. The production principle is based on the production process of ceramic products, which reduces the cost of the former for walls and floors, and also improves the quality of ceramic products. performance and appearance experience.

The crystallized glass veneer with a surface thickness of 2.5mm is attached to the surface of the special ceramic body and is crystallized at a high temperature of 1200°C. It has a stable structure, does not contain any organic auxiliary materials such as adhesives, has a surface whiteness of over 90, almost no water absorption, is resistant to acid and alkali corrosion and is easy to clean. It is widely used in indoor and outdoor wall and floor paving, and is the best substitute for natural Thassos.

Regular sizes are 60 x 60 cm, 80 x 80 cm and 60 x 120 cm, and the current product design is 1.3 cm thick. In the application of wall and floor coverings, transportation, loading and unloading processes and cutting processes are more convenient and cheaper than glass panels.

Foamed Crystallized Panel

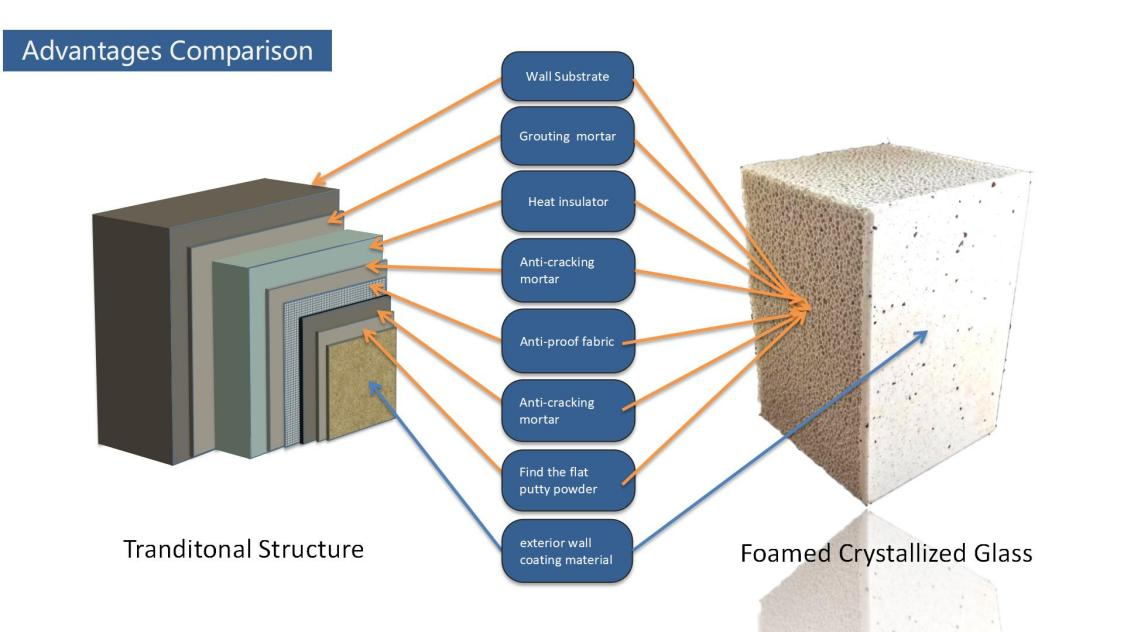

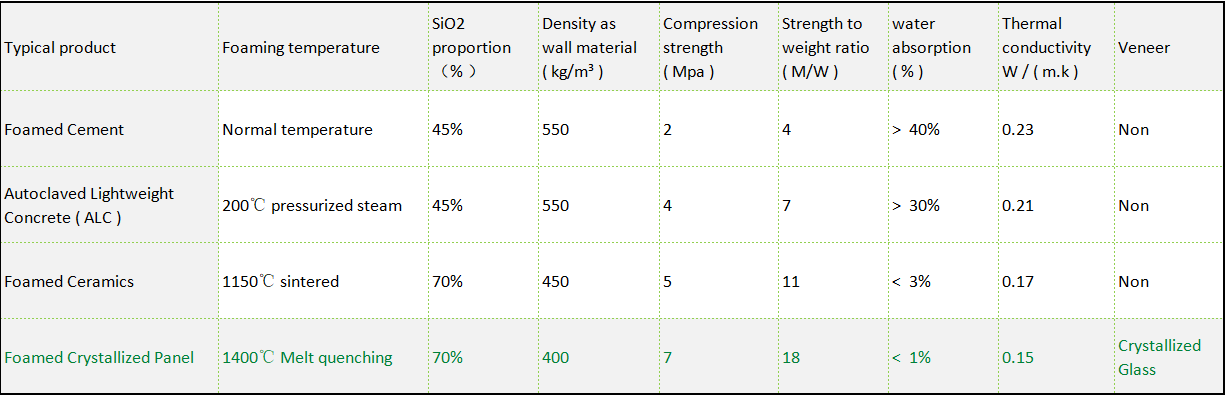

Continuous product development and updating is the basis for the sustainable development of China's microcrystalline stone industry. The new generation of Lightweight Microcrystalline modified thermal insulation integrated board can be directly used as the latest material for building walls.

The decorative layer of lightweight microcrystalline stone and the microcrystalline foam are integrated and sintered at high temperature. The decorative layer has a dense microcrystalline structure and the related properties of microcrystalline stone. The microcrystalline foam has microcrystalline honeycomb holes. structure and superior performance to existing inorganic foam materials. Lightweight microcrystalline stone therefore integrates the complementary properties of both materials, which constitute its superior properties.

The foamed glass-ceramic board has the characteristics of "light weight and high strength, energy saving and heat preservation, waterproof and anticorrosion, fireproof and flame retardant, integrated decoration, durable and shockproof, quick construction, healthy and comfortable, and green and environmental protection". It is an ideal combination of current steel structure and concrete frame structure.

Nano Crystallized Glass Stone

China's original nanocrystalline glass is a high-quality building decoration material, which is made from raw materials and fired into slabs through a calendering process at 1600℃. Due to its amazing physical and chemical properties, it is widely used in indoor and outdoor decoration of commercial buildings and residences.

Performance

Nanocrystalline glass is a stone refined from high-purity silica, natural quartz sand and other raw materials. It is much harder than standard crystalline glass or even natural granite, with a Mohs hardness of 6.0 to 7.0, a compressive strength rating of 400 MPa, a bending strength rating of 82 MPa, and a breaking strength rating of 35 MPa. The main features are as follows:

1. High hardness: The hardness of Nano Crystal Glass can reach Mohs hardness level 7, which is 5-7 times that of ordinary marble and granite, so it has extremely high wear resistance and impact resistance.

2. Strong stain resistance: After the surface of Nano Crystal Glass is polished, it can effectively resist the erosion of stains and moisture, and is easy to clean.

3. Good oxidation resistance: Nano Crystal Glass has excellent oxidation resistance, can withstand the erosion of different climates and environments, and is not easily affected by oxidation.

4. No radioactivity: Nano Crystal Glass uses high-purity raw materials, does not contain radioactive substances, and is environmentally friendly.

5. It can be reheated and bent to form a curved surface or an arc surface. The cost of making a cylindrical surface is lower than that of natural stone, and it is easy to install. The sink and washbasin made of it are more stain-resistant than acrylic materials and easy to clean and care.

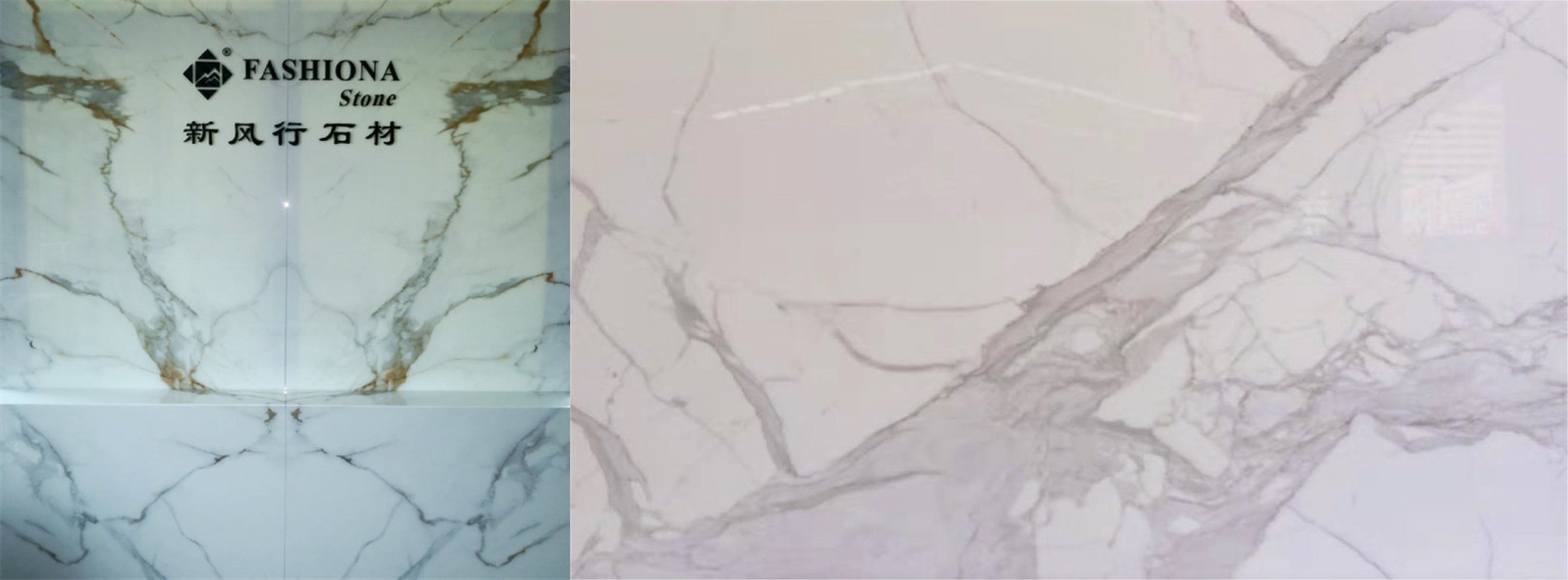

In addition, the surface texture of Fashiona Nano Crystal Glass can be customized: with the mature application of 3D inkjet printing technology, the surface of Nano Crystal Glass can be made into a variety of marble textures, such as Calacatta, Carrara and high-end luxury stone patterns.

Care and maintenance

Nano Crystal Glass has very excellent anti-fouling properties, which can effectively resist the erosion of stains, and usually only needs to be wiped with clean water. However, if there is a stain that is difficult to clean, it can be wiped with a special cleaner. In addition, when Nano Crystal Glass encounters chemical substances such as strong acids and alkalis, it is easily corroded, so direct contact should be avoided.

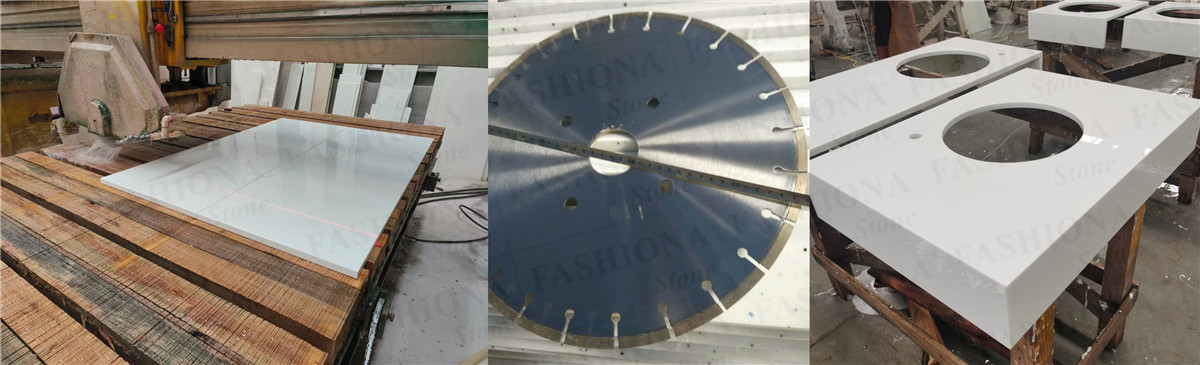

Cutting

During the processing of Nano Crystal Glass, the hardness is very high, which requires the use of high-speed electric stone cutting machines, polishing machines and other equipment. During the cutting process, it is necessary to pay attention to the width of the band mark and the cutting speed of the equipment, and at the same time maintain a stable and sufficient water injection to avoid adverse effects such as excessive temperature and deviation of the cutting path.

Application

The surface of Nano Crystal Glass is smooth and smooth, with a wide range of temperature changes, non-absorbent, acid and alkali resistant, will not fade and change color, and has a long service life. It is more durable than quartz stone, acrylic and other synthetic stones. It is especially suitable for covering materials for kitchen and bathroom countertops.

Nano Crystal Glass has super wear resistance, and the floor covering can create a transparent, bright and simple feeling. Because of its non-water absorption and anti-oxidation properties, the Nano Crystal Glass floor will not appear in reverse osmosis, oxidation and corrosion of natural stone.

Recycled Crystal Glass Panel

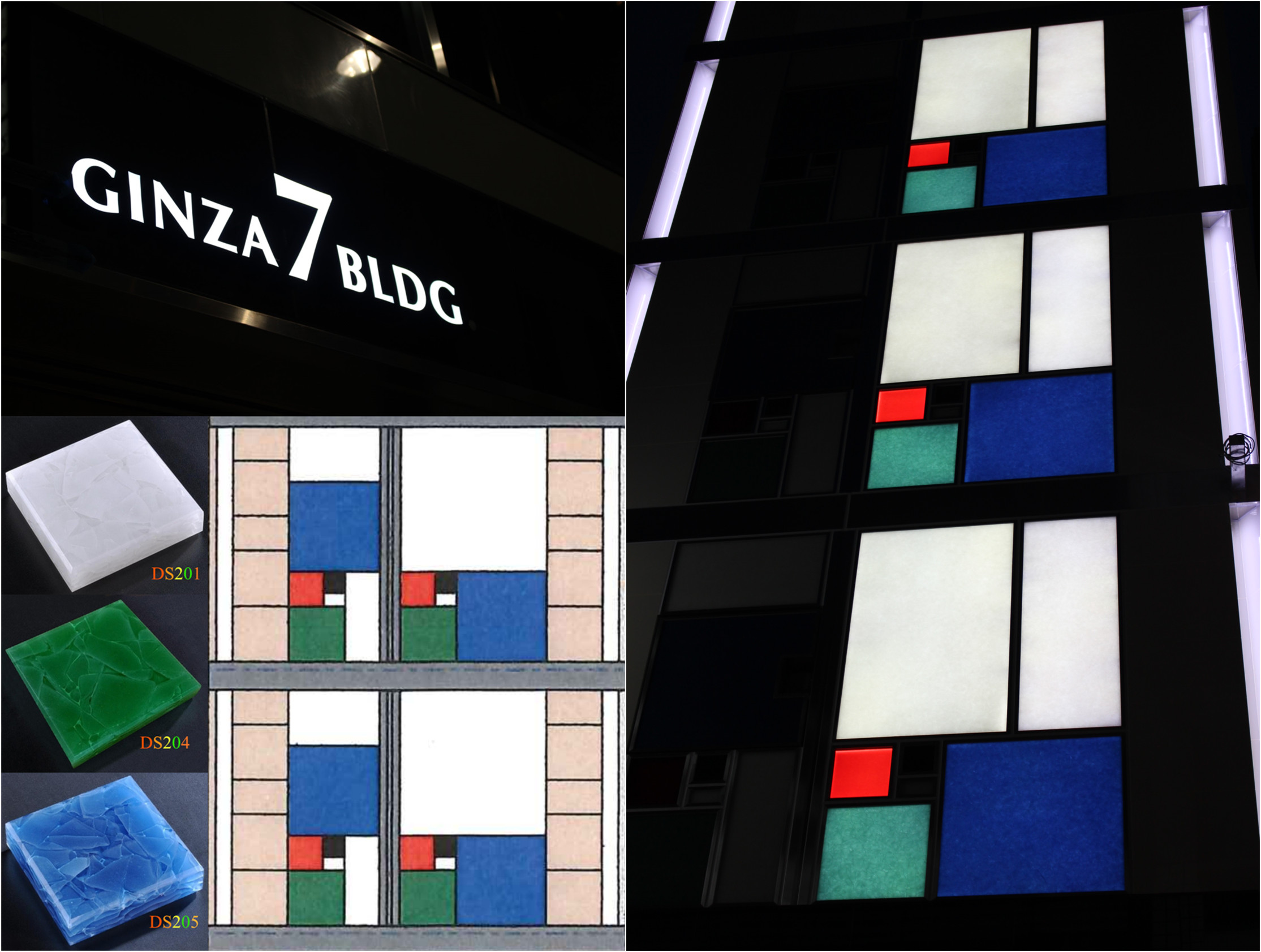

Crystallized glass is a technical innovation of ordinary glass, transforming from a transparent material into a solid stone function; while recycled crystal glass makes full use of discarded industrial glass from the perspective of environmental protection, and the glass bottle fragments are crystallized again at high temperatures Made of semi-transparent sheet.

It is a construction and interior and exterior design material made from 100% recycled glass and does not contain any resins or other additives. It has a unique translucent optical effect, which can produce a crystal-like brilliance effect through direct light irradiation and refraction or the backlight of LED cold light source.

FashionAglass uses crystallization technology native to China. It is the only one in the crystallized glass family that can achieve translucency, and its various properties fully meet the specifications of stone. This is unmatched by all low-end resin light-transmitting panels. Its UV protection function is more suitable for outdoor urban architectural design and building exterior curtain wall covering.

The Slab size we designed is 3000 x 1400 mm and 2600 x 1200 mm, and the thickness is 20 mm and 30 mm. Having a complete set of cutting and processing equipment is enough to achieve a variety of application effects in the design.

China has the world's largest waste glass production industry, which provides a controllable source of raw materials for our production and enables a rich product color system. This business philosophy of “turning waste into treasure” is also our social contribution to purifying the environment.

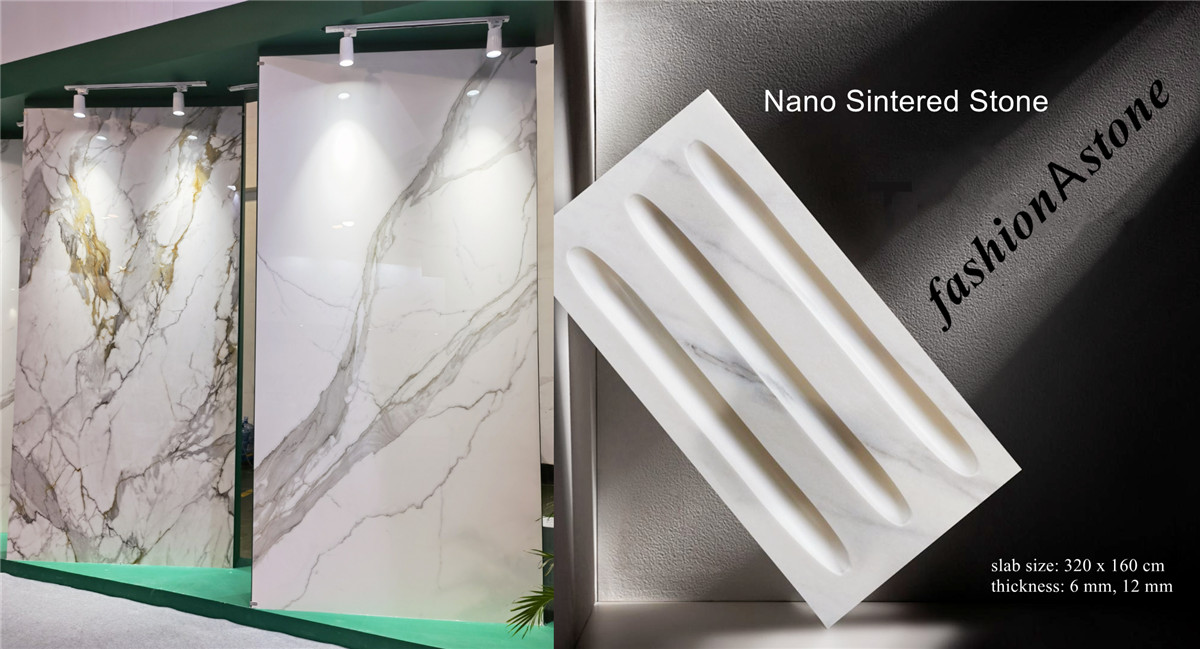

Nano Sintered Stone

Continuous innovation is the eternal development concept of Fashionastone. Since 2001, our professional team has been committed to the research and development, production and sales of glass-ceramic stone in China.

Following the first generation of sintered microcrystalline marble to the second generation of calendered nanocrystalline marble, our industry has integrated the mature technology of ceramic sintered stone and crystallized glass, and has successfully developed and started large-scale production of a new generation of inorganic slab--Nano Sintered Stone (NSS).

NSS has changed the multi-layer fabric process of porcelain slabs, and truly realized the integration of materials; At the same time, NSS has broken through the technical limitations of porcelain plates and glass-ceramics that can only allow the texture to stay on the surface, and has completed the whole body. So we call it "dual integration" of material and texture.

The successful research and development of NSS marble is a new pioneering work in China's artificial stone industry. The sintering process reproduces the formation process of natural Calacatta under the high temperature condition of 1200 ℃. Excluding natural stone and most man-made stones, it is inorganic and UV-resistant compared to quartz surfaces.

NSS maintains the non-absorbent, fireproof, high temperature, acid and alkali corrosion, and UV protection of the original crystal, and achieves food-grade hygiene and safety. The whiteness of the embryo body reaches more than 75 degrees, which truly reproduces the elegant and luxurious texture of Italian Calacatta marble.

The current maximum size of NSS boards is 3200×1600 mm, with thicknesses of 6 mm and 12 mm. After subsequent equipment improvements, the thickness of 18mm~20mm is expected to replace the application of organic quartz slabs, especially the best substitute for expensive natural Calacatta and Cararra marble.